Cayuga Digester

The Cayuga Regional Digester Facility processes organic food waste from local farms, grocery stores, and other food processors into a renewable energy source. Examples of organic food waste processed in this facility include outdated soda/beverages, expired produce, and other perishable items.

After the food is anaerobically digested, and utilized as a renewable energy source, the by-products are utilized locally. The remainder of the product is then used as a high nitrogen content fertilizer for the farming community.

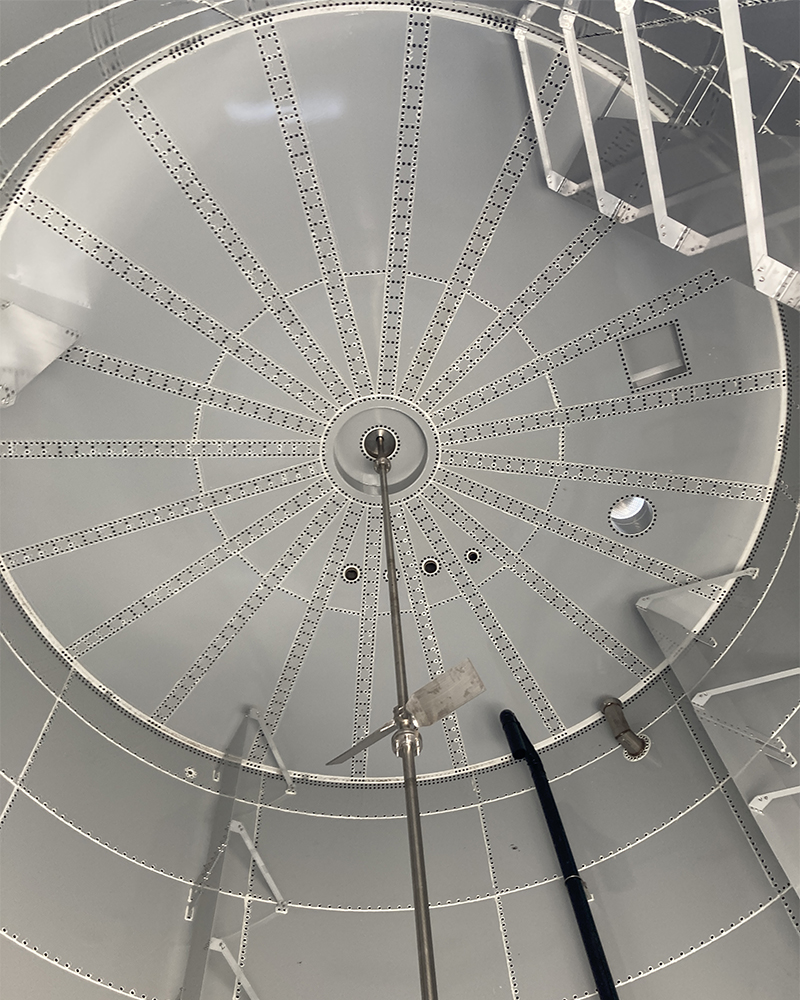

In support of the C&S Engineers, Inc. design for this project, C&S Technical Resources, Inc. provided process piping services, as well as millwright services to support the installation of three large digester tanks and their associated equipment.

Process piping scope of work included installation of carbon steel glycol piping, high density polyethylene process piping, and 316L stainless steel piping glycol to support the digester process both within the tanks and outside of the tanks. Installation of all controls related instrumentation such as level sensors, temperature sensors, and control valves was also provided.

Millwright services included rigging and installation of glycol heat exchangers, as well as installation and modification of the 60′ long mixer within the tank. C&S worked with a local crane company to preassemble the mixer on the ground, and rig into place assembled requiring significantly less in tank work.